Product Filter

Disco-DFD6750

Availability: Product not in stock!

Supports other workpiece sizes

Facing dual spindle

Package Singulation

Next generation dicing engine featuring dual chuck tables for improved productivity

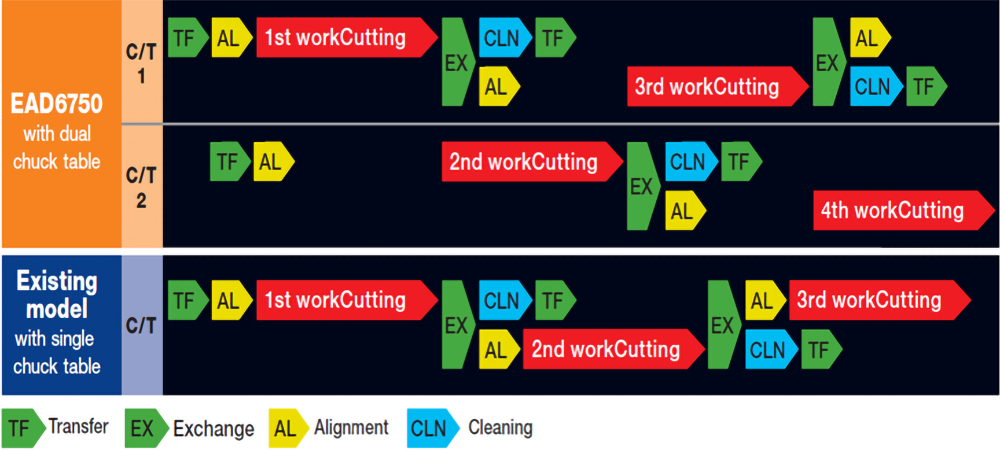

The DFD6750 is a dicing engine that provides significantly raised productivity. It also incorporates two chuck tables to enable one table to perform cutting while the other is simultaneously transferring, aligning, and cleaning. This results in a substantial reduction in spindle processing wait time for higher productivity. The return speed of each axis is also increased for improved throughput.

Increased processing quality

An improved vacuum mechanism is used to provide stronger workpiece suction in order to reduce workpiece warpage and achieve higher quality.

Improved countermeasures for remnants

To better handle remnants, a high durability stainless steel cover is used instead of a bellow to reduce the risk of remnants damaging the bellow. A brush unit is also used to enable easy collection of any remnants.

Process flow comparison with existing model

Meeting the need for traceability

Since the DFD6760 is equipped with two chuck tables, while dicing is performed on one chuck table, kerf images of the workpiece after processing can be saved and processing quality can be recorded using the other chuck table. In recent years at production facilities, there has been a demand for traceability. If a defect is found in a device, theDFD6760 can provide the records to check or certify product quality.

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.