Product Filter

DFD6362

Availability: Product not in stock!

Φ300 mm Facing dual spindle

Realizes further productivity improvement with various new functions

DFD6362 offers a higher dual cut processing speed due to the shortened distance between the spindles. Enhanced axis mechanism improves the X-axis return speed and optimization of the parts used achieves higher speeds for the major transfer unit, resulting in a throughput improvement of approx. 7% compared to the previous model under the same condition

Improves full cleaning capabilities

DFD6362 uses a wheel cover effective against particle adhesion based on water flow analysis in the vicinity of the processing section. In addition, a chuck table water curtain (CTWC) and atomizing nozzle for wheel cover can be selected as an option to suit specific workpieces.

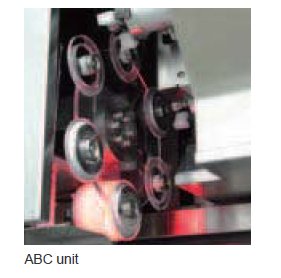

Automatic Blade Changer (ABC) *optional function

Fully automates the blade replacement and precut procedures after blade breakage and at the end of blade life and restarts processing, thus reducing operator workload. Since it takes sixty seconds to replace a blade, the ABC leads to substantially shorter downtime. The equipment scans the 2D barcode on the backside of the blade containing information on the blade type, preventing potential human errors during blade replacement.

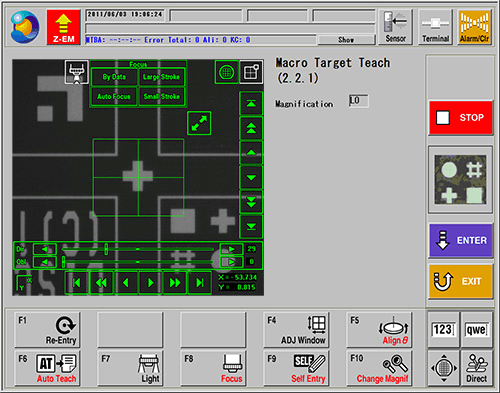

Advanced graphical operation software

Realizes an improvement in operability by setting operation buttons on the same screen as the microscope picture, especially when performing operations such as the teaching operation. Also, the software is able to display the equipment operating conditions in a clearer and more understandable way by graphically representing the equipment conditions.

DFD6362 Operation flow

-

Lower arm moves the workpiece from the cassette to the pre-alignment stage. Lower arm moves the workpiece to the chuck table → cutting →

-

Upper arm moves the workpiece to the spinner table → cleaning & drying →

- Lower arm returns the workpiece to the cassette

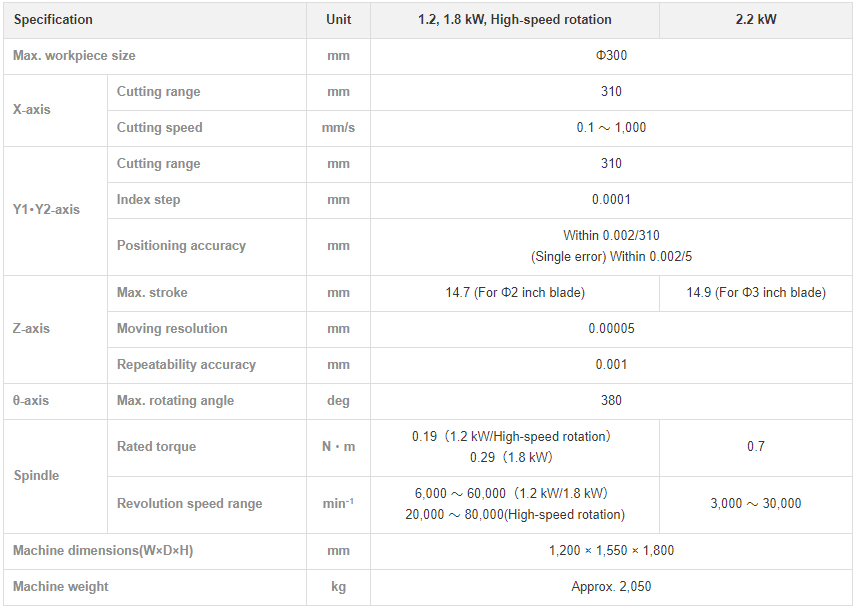

SPECIFICATION:

*Product appearance, features, specifications, and other details may change due to technical modifications.

*Please read the standard specification sheet thoroughly before use.