Product Filter

Disco-DFD6363

Availability: Product not in stock!

Φ300 mm

Facing dual spindle

DBG

Compatible with both frame and two-way*(frame/wafer) transferring

Various processes, including full cut and half cut, can be supported with only one DFD6363. Size conversion operations can be reduced, reducing human error. Supports both standard cassettes (Φ200 mm / Φ300 mm) and FOUP cassettes.

*Option

ABC (Auto Blade Changer)*

This feature minimizes equipment downtime by automatically detecting the end of blade life and performing all operations from blade replacement to continuing processing in fully automatic operation. It also prevents potential human errors during blade replacement due to workpiece changes and is effective for improved traceability.

*option.

Basic function improvements

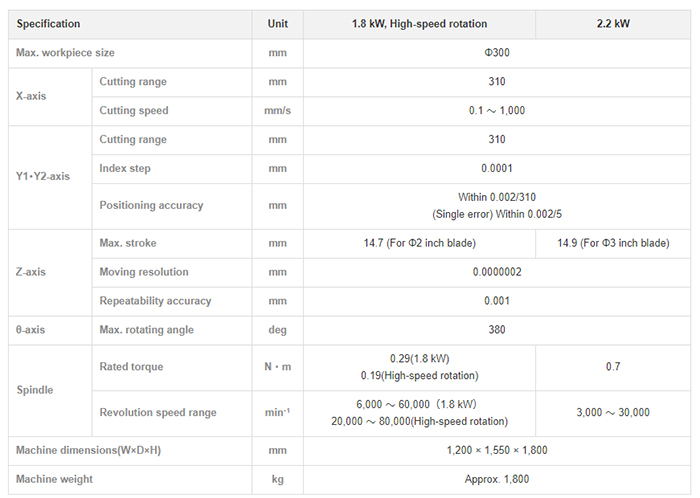

DFD6363 offers improved usability through the adoption of a 19-inch monitor and highly visible GUI (Graphical User Interface). It also achieves reduced processing time by optimizing the axis operation through multiple-axis synchronous control. Can expect improved productivity with the improved NCS (Non-Contact Setup)* and stable processing with the mounted specially developed 1.8 kW spindle (60,000 min-1)

*option.

Operation flow

(For frame transfer spec.)

-

The lower arm retrieves the workpiece from the cassette. Centering is performed at the pre-alignment stage. The lower arm moves the workpiece to the chuck table. → Cutting →

-

The upper arm moves the workpiece to the spinner table. → Cleaning and drying →

- The lower arm returns the workpiece to the cassette.