Product Filter

TM11 Series

Availability: Product not in stock!

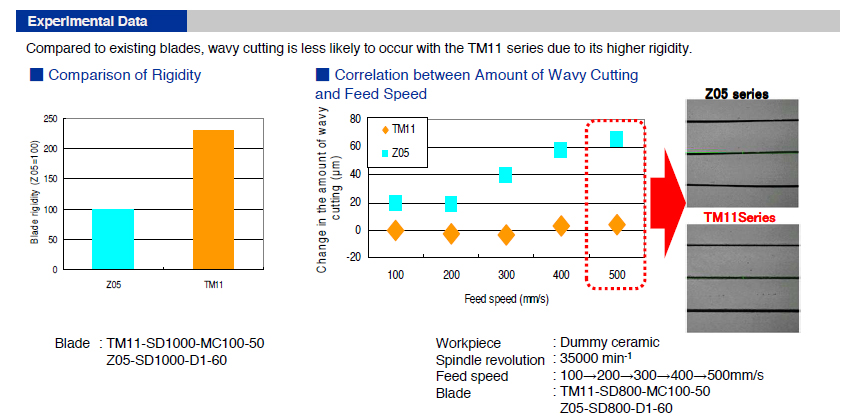

Metallic blades that realize higher rigidity

Improved blade rigidity

By employing a high-rigidity bond, the TM11 series realizes a higher rigidity which exceeds that of electroformed blades, preventing wavy and slanted cutting, and improving processing speed.

Improved blade rigidity

By employing a high-rigidity bond, the TM11 series realizes a higher rigidity which exceeds that of electroformed blades, preventing wavy and slanted cutting, and improving processing speed.

Exhibits the full ability of a thin blade

Even in applications which use thin blades, the TM11 series achieves highly parallel processing and improves processing speed and quality by upgrading the rigidity.

Stable processing is possible due to long blade exposure

Due to its high rigidity, the TM11 series is good for applications that require a long blade exposure.

To use these DISCO blades and wheels (hereafter precision tooling) safely...

Please read carefully and follow the instructions below to prevent any accidents or injuries:

- USE a safety cover (nozzle case, cover), equipped as a standard accessory, to avoid injury.

- DO NOT EXCEED the specified rpm limit indicated on the precision tooling.

- FOLLOW the instruction manual of the equipment to mount the precision tooling properly.

- DO NOT DROP OR HIT the precision tooling. This may cause breakage or injury.

- Always CHECK the precision tooling for chipping or any other damage before starting to use it. DO NOT USE the tooling if there is any damage.

- READ the operation manual of the cutting/grinding equipment before use.

- DO NOT USE the precision tooling with modified or customized equipment.

- DO NOT USE precision tooling that has a different size from the one recommended for your equipment.

- DO NOT USE the precision tooling for any other purpose than grinding, cutting, or polishing.

- Always USE water or coolant to prevent precision tooling damage.